|

"How do I price my work?" is a question literally every plush maker asks, including me. It's an extremely difficult question to answer and depends on a lot of variables. There is also no right or wrong way to do it, and it's very subjective.

So here are my thoughts on the subject as well as how I price for my work. Get some coffee, this is a long one! Why you shouldn't undercharge for your workPerhaps the #1 lesson to take from this guide is to make it your goal to not undercharge for your work, which is why I've placed this section at the top. I say to make it your goal because

So why is it so important not to undercharge?

Let's talk through a made up example of what can happen if you undercharge for your work (and make several other bad decisions). The Nightmare Scenario

(I made up this example; it did not happen, so please don't think less of me).

But let's break down this price:

This situation results in me making <$2 an hour- not to mention I will have to work nonstop making the same exact item every waking moment to try and fulfill these orders (assuming I don't already have another job!) If you applied for a job and they offered you $2/hour and 100 hour weeks, would you accept it? Probably not! (Fwiw, federal minimum wage in the United States is $7.25/hour as of writing this guide). I quickly become overwhelmed with having to fulfill 500 orders. I lose my inspiration to make these plush. Even though I get better at making them, I slow down after a while because I have no more motivation. My communication with my customers falls through, partly because of the sheer volume of clients. I miss the 2 week deadline on most of the orders. My customers begin to think they are being scammed, even though I'm working on the orders and I literally don't have time to respond to all the messages. The chargebacks begin, and I lose even more money. Beware posts begin to be made about me, and I lose credibility within the community. Sounds awful, right? Sadly, this scenario happens, outside of the plush making community as well. It's important to keep in mind that you are running a business by selling custom plush and you need to operate responsibly. Premades vs. CommissionsI highly recommend new plush makers to start out by making premade plushies rather than taking commissions or "made to order" plush. Why is that?

Should you price premades differently than commissions? No, but you can learn a lot by making some premade plushies and start to get a feel for whether this plush making thing is really for you. Pricing FactorsSo what factors should you consider when pricing your plush? Here are a few minimum factors to consider:

Let's break down each of these factors. Cost of Goods Sold (COGS)

If you've taken an economics class or established yourself as a registered business (reality check: if you operate with the intention to make a profit, you are running a business in the eyes of the IRS), you should know what Cost of Goods Sold (COGS) is. It's exactly what it sounds like: how much does it cost for you to make that good that you're selling?

Measurable expenses I'm defining "measurable expenses" as materials that you can easily/reasonably determine how much goes into a single plush by measuring with a measuring tape, weighing, etc. This would be things like fabric, stuffing, poly pellets, etc. For example: You need to order some minky for your commission/premade plush. It only takes 1/2 yard to make it, but you can only buy it in 1 yard increments. Is your COGS based off 1/2 yard or 1 yard? In the eyes of filing your taxes for the IRS: it's based off the 1/2 yard (down to the exact amount to be precise). In the eyes of your pricing: it's whatever you want! If you want to charge for the full yard because you had to pay $14 for the full yard even though you only used $7 worth, that's perfectly fine. Perhaps if you're buying specialty fabric that you don't foresee yourself using again in the future you would charge for the entire cost. But if you're struggling to make sales because you feel like you're overpriced, perhaps you're overstating your material costs and you can reevaluate. For stuffing, you can weigh the stuffing you put into a plush. You can buy a scale (which I highly recommend having for shipping purposes), weigh the unstuffed plush before you stuff it to determine how much the fabric weighs, stuff the plush, and then weigh it again. The difference between the stuffed plush and the fabric weight is how much stuffing you put into it. Then apply some math to figure out the cost! Example: 1000g of stuffing = $20 Amount of stuffing used in a plush = 100g Percent of stuffing used = 100/1000 = 0.1 or 10% Cost of stuffing used = $20*10% = $2 You can extend this example to nearly all sewing supplies as you typically do not use up an entire cut of fabric, an entire bag of stuffing, an entire spool of thread, etc. on a single plush. If you tend to have to remake parts of your plush or need to also pattern it, make sure you account for those materials as well! For example, I usually always have to remake the heads on my plushies because something isn't right. I can double the amount of fabric used in a head when estimating the COGS for one of my plushies. But how do you account for expenses like that spool of thread I mentioned that is completely impractical to measure by the yard? Non-measurable expenses I'm going to call these "non-measurable expenses": they are impractical/impossible to measure like how much thread you use or basting spray. You can also bucket things like tools/equipment into this category like your sewing machine & associated repairs/maintenance, pins, scissors, etc. This is more difficult to calculate because by definition, it's not measurable. You can certainly apply a similar practice as the "1 yard vs. 1/2 yard" example above and charge for entire spools of thread that you buy for a certain project, an entire bottle of fragrance oil, etc. But you can consider trying to convert these non-measurable expenses into a general amount per plush. You can start by asking:

To answer #1, can you figure out how much you spent in prior years? Do you have your receipts? (If you use Paypal/buy things online, you'd be surprised at what you may still have). Was that an average year or a below average year for expenses? How about the number of plush you made in that year? How many years of data do you have to help determine an average? If you divide your expenses by the number of plush you made you can turn this into a flat amount. Example: Estimated non-measurable expenses in a year = $500 Estimated number of plushies in a year = 20 Amount to be added per plush = $500/20 = $25 Now if all the plush I'm selling are $200 each then adding an additional $25 might not be an issue. But what about a tiny $20 plush? I can't exactly add $25 to the price of that! It might be better for you to think in terms of percentages rather than flat dollar amounts. If you can get a feel for how much you spend on measurable expenses vs. non-measurable expenses, you can apply a percent to your measurable expenses to account for non-measurable expenses. First of all, how do you charge for your measurable costs? Do you account for the 1/2 yard you actually used or the 1 yard you had to buy, even though you have 1/2 yard left over? It's important to account for this in your math because you can literally be off by a factor of 2 to 4+! In 2021, my actual COGS according to the IRS (so, the 1/2 yard I actually used and not the 1 yard) was about 1/4th of the total measurable supplies I actually bought! (For tax purposes, I can only claim the used amount, but for pricing purposes I can certainly charge for the full amount). Relative to the total amount of measurable supplies For example, let's say you've collected all your itemized receipts and believe that, on average, you spend about the same amount on non-measurable expenses compared to measurable expenses. This is relative to the total amount you spend on measurable expenses and not the actual amount that goes into a plush. This means you should multiply your measurable material costs by 2 to determine total material costs for a plush. Example: Estimated measurable COGS in a single plush (total purchased) = $20 Estimated non-measurable COGS in a single plush = measurable COGS = $20 Total material costs = $20+$20 = $40 Relative to the used amount of measurable supplies What if you price for your plushies based off the amount used and not the amount purchased? You can still figure out this relativity, it just takes extra data collection. You will need to figure out how much measurable supplies you actually used in previous years. It's easiest to keep track of this as you make things but you can also perform inventory at the end of the year (not going to go into this topic here). When you relate non-measurable expenses to used measurable expenses the relativity will be higher but your measurable expenses should also be lower. If 1/4 of the supplies I buy actually go into my plush: Example: Estimated total measurable supplies purchased = $500 Estimated used measurable supplies = $125 Estimated non-measurable supplies = estimated total measurable supplies = $500 Ratio of non-measurable supplies to used measurable supplies = $500/$125 = 4 This means you need to apply a factor of 4 to your used measurable materials to determine non-measurable materials. Estimated used measurable COGS in a single plush = $20*1/4 = $5 (or preferably, measure directly) Estimated non-measurable COGS in a single plush = used COGS*ratio of non-measurable to measurable = $5*4 = $20 Total material costs = $5+$20 = $25 You can see that we arrive at the same amount of non-measurable goods in both methods, but the total costs are different because of how the measurable goods are accounted for. With this method of scaling your non-measurable expenses with measurable expenses, the material costs will scale appropriately with each other, avoiding the issue of charging $25 in supplies on a $20 plush. However this method is a little riskier because if you don't sell enough in quantity or high dollar plushies you might not earn back the total amount needed. For example if you need to cover $500 in non-measurable expenses and you only sell 50 $20 plushies that have $2.00 in non-measurable supplies then that's only $100 that you've recovered! So it's important to make some projections once you determine your method and make sure that everything makes sense, and to see what happens if you run into more extreme scenarios like this. Overhead

Here's another difficult one to price: the costs of running your business that aren't from materials or tools. This can be things like rent, internet, electricity, etc.

You may want to take a similar approach as my recommendation to non-measurable expenses: determine how much you want to attribute to your business in a year and figure out a reasonable method to apply this to your expenses. For example, if you have a sewing room or a dedicated sewing space, you can figure out the percentage of space this room takes up in your house and apply this percent to the rent or mortgage cost. For internet you can try to estimate how much time you spend on the computer/phone running your business compared to your casual time. So if you spend 25% of your time on the internet working and 75% of your time casually, you could apply 25% of the cost of internet towards your prices. After totaling this all up, you'll also have a dollar amount that you want your plushies to cover in a year. How do you apply this though? You can also determine a flat amount to apply per plush or you can apply a percent charge to measurable COGS, as demonstrated in the COGS section. Shipping Costs

The most fool-proof method is to explicitly charge for the cost of shipping rather than bury it in the price of the plush itself.

For premades, you will want to package up the plush as if you were about to ship it. Weigh and measure the package (if you don't have a scale, you absolutely should get one). If you're using a site like Etsy you can put these figures into the site and Etsy will calculate the shipping costs for you upon checkout. If you're using a site like Big Cartel that does not calculate shipping or if you need to charge the customer yourself, use a site like Pirate Ship to determine the shipping cost. For commissions I prefer to wait until I have finished the plush (or nearly finished it) so I can also figure out what box I need to ship it in to accurately calculate costs. It's also important to not estimate too early and to periodically reevaluate costs as needed since carriers can increase their rates, usually annually. If you need to calculate sales tax, you should figure out if your state also charges sales tax on the cost of shipping! Don't forget to also account for the cost of shipping supplies: boxes, packing material, labels/stamps, etc. Lastly, you also need to increase the cost of shipping to account for Paypal or other fees. Paypal will take a % of the shipping amount you charge, so you need to adjust accordingly. Time Spent

The best way to figure out how much time you spend making a plush is to literally track it with an app or with a stopwatch (which you can also use an app for!). Of course this is fine for premades which you can price after you make one, but what about commissions where you need to predict how much time you spend?

This is where you need to have some experience under your belt. When trying to predict how much time you will spend on a commission you need to have at least some kind of idea of a baseline to relate it to. You need to ask yourself questions like:

To help me be able to predict the time spent on my own commissions I typically will make an example plush before offering it as a commission type. For example when developing my anthro pattern I made a plush that I could show as a sample to interest clients and it also helped me figure out how much time it would take to make one (and materials). Let's talk through an example.

Let's say I'm asked to make a plush of the character on the right, Drago, and I plan on using my lying Neko Atsume pattern as a base (left). (I made this plush as part of a trade so I did not price this plush out but here would be my thoughts if I did)

We'll start with how long it takes for me to draft the concept, plan all this out, price it, and buy the materials; let's say 1 hour to do this. From my experience making a few of these Neko Atsume plush in the past I know it takes me about 3 hours to cut out the fabric, sew it together, and stuff it, without doing any embroidery. So I know Drago is going to take at least 4 hours. But Drago requires special patterning besides his extra details: his neck, head, tail, and feet will need to be adjusted from my starting point. I know from my own experience usually it takes me 2 attempts to get a pattern right. Let's say I estimate it'll take me 1.5 hours to pattern the neck (estimating 2 attempts at 45 minutes each); 2 hours to pattern the head (2 attempts at 1 hour each); 30 minutes for the tail (1 attempt as I've made many triangular tails before); and just 15 minutes to figure out 1 of the feet (don't need to pattern all 4; just transfer the pattern to the other legs). That adds up to 4 hours and 15 minutes of extra patterning, so now I'm at 8 hours and 15 minutes to make this plush. What about the embroidery? On a plain single color Neko Atsume plush with only a face it would take about 30 minutes to prepare the embroidery, hoop the fabric, execute it, and finish it up. Drago requires embroidery on 3 sides of the head (one of them with a 3D tongue), stripes on the belly and tail, and his knee/elbow pads on the 2 sides and tummy patterns. First of all, I need to design all of this in my embroidery program. Let's say each one takes 15 minutes on average to do. Some of them are mirrored, so I only need to account for 5: 5*15 minutes = 1 hour 15 minutes. Now I'm at 9 hours and 30 minutes. Let's assume that when I execute this embroidery, since I'm doing all of this at once I am more efficient than 30 minutes per embroidery at 20 minutes per embroidery (I'm not going to check for this example but your embroidery machine should tell you how long it takes to stitch out a design, so you can use this to help calculate). Let's break this down:

What about sewing it all together? These extra details are going to take longer. Let's say it'll take 15 minutes per foot (15 minutes*4 = 1 hour); 30 minutes for the tail; and 1 hours for the head and neck, so an extra 2 hours and 30 minutes. 14 hours and 50 minutes total. What about the extra details like the spikes and tail tip? The back spikes would be machine sewn into the back of the plush, so let's just say making 6 and sewing them in would take (5 minutes each*6 = 30 minutes + 10 minutes to sew them into the seam = 40 minutes total). The tail tip would be machine sewn then hand sewn on, so let's say 20 minutes for a total of 1 hour. 15 hours 50 minutes. Because this is a trade, I'm going to assume that I'm not going to do any revisions. But how would I handle this for a commission? Well, from experience I know that I typically have to remake the head of a plush pretty much every single time. So I would estimate how long it would take for me to remake a head and adjust accordingly. For your own commissions you should determine how you handle revisions. Are you going to bake them into the cost of the plush? Or are you going to charge for each revision? It's important that you establish this before accepting the commission and putting it in your TOS. Obviously charging for revisions after the fact is easier, but some might be put off by this practice. Let's round this up to 16 hours to be even. Add 30 minutes for invoicing and shipping. So I've estimated that Drago will take about 16.5 hours from start to finish. However one thing you should consider is additional padding in case something goes wrong. What if you had an extra revision you didn't expect? What if something takes longer than you estimated? Let's just round up the total hours spent to 17 hours, just in case. But how much do I charge per hour? Hourly Rate

Here's one of, if not the biggest question you'll ask yourself. What do I charge per hour? Here are things to consider:

You can consider as many factors as you want (and much more than I have listed!) Supply & Demand

Part of your consideration in pricing should be your supply vs. demand. This is the dynamic between how much product you can supply vs. how much demand there is for those products.

Sometimes it's difficult to separate supply & demand from your reach as an artist. But you can generally link your reach/popularity (I hate to use that word, but it's the easiest one to use here) to demand. When demand is greater than supply You'll know if your demand exceeds your supply when you have situations like:

When demand is less than supply You'll know if your demand is less than your supply when you have situations like:

This generally means that you are overpriced and can lower your prices if you feel the need to move your product. If you do not need to sell your premade items urgently, there is nothing wrong with letting them sit in your shop. (My Growlithe plush took over 3 years to sell even after lowering the price a couple times). But then you might want to investigate things like advertising, whether your shop has appropriate reach (are you on Etsy or a smaller platform like Big Cartel?), etc. Finding the happy medium between supply and demand is the goal! You don't want to be overwhelmed by commission requests and you don't want too few, either. It's also important to keep in mind that different times of year will have different demand. The months/weeks leading up to big gifting holidays (Christmas, Valentine's Day, etc.) will naturally have higher demand than some other times of year. For example, many artists do not get a lot of commission requests in mid/late December since people need their gifts earlier (and have spent a lot of their money already!) When you're first starting out your demand will generally be lower than your supply as you grow your clientele. If you're super lucky and make a popular product your base can grow very quickly! This is one reason why it's smart to not "lock" yourself into the price of a large amount of orders. Fees

No matter what selling platform you use, you are going to have to pay fees on the transaction. It's super important to account for these in your pricing as you can lose AT LEAST 5%+ on every sale!

These fees vary widely by selling platform (Etsy, Big Cartel, Shopify, etc.) and by payment platform (Paypal, Square). You need to do your research on how much these fees are. They can also vary for international sales due to currency differences! So you may need to charge even more for international sales. You should calculate the total price of your plush including all factors previously discussed and multiply them into the total. For example, if your price was $500 before fees, and you have 3.49% fees from Paypal to account for, your new price should be $500*(1.0349) = $517.45. It's up to you if you decide to round up or charge this exact amount. It's worth noting that it's against many platforms's TOS to explicitly charge a customer for fees. Because of this you do not want to "line item" any fee in your invoice; just bake it into the cost of the plush. It's very important to keep up to date on what the fees are by platform. They increase frequently, and often by very large amounts. Taxes

Because you are a good tax-paying citizen, you need to consider the cost of taxes in your work. I am not a tax expert so I generally just consider a 30% loss in my revenue to taxes (excluding shipping). This means that I should raise all of my prices by 30%. If you want to cross your T's and dot your i's you should look into this further.

State sales tax is a different beast - as a business you are supposed to be collecting and remitting the sales tax for an item to your state and any other state you have nexus in. But this is added to the invoice directly, and you just hold onto it until you pay your taxes to your state. So this doesn't need to be accounted for in your prices (but you need to make your customers aware that you need to charge sales tax if you are invoicing them directly). Putting It All Together

Let's go back to my example above using Drago.

I've determined that he will take 17 hours to make. Above, I've decided my hourly rate for this year is $25/hour. That brings me to $425. I need to account for materials. I've estimated that my measurable materials will cost $10. I will multiply this by 2 to account for my non-measurable expenses or $20. Adding these together gets me $30 in materials total. I don't account for overhead in my pricing because I work out of a room in my home, even though I could, so I'll just leave it at $30. This brings the total to $455. To account for any Paypal fees I increase the price by 3.49% (the current fee); so $455*(1+3.49%) = $470.88. To account for taxes multiply this by 1+30% (my assumed tax rate). $470.88*1.30 = $612.14. Let's just round this off to $615. This doesn't account for shipping, which I would charge separately. I would also increase the cost for the cost of shipping supplies, the cost of the label, and Paypal fees. Another Method

So do I use the exact method above to calculate my prices? Actually no, I don't. It's similar in concept but applied differently.

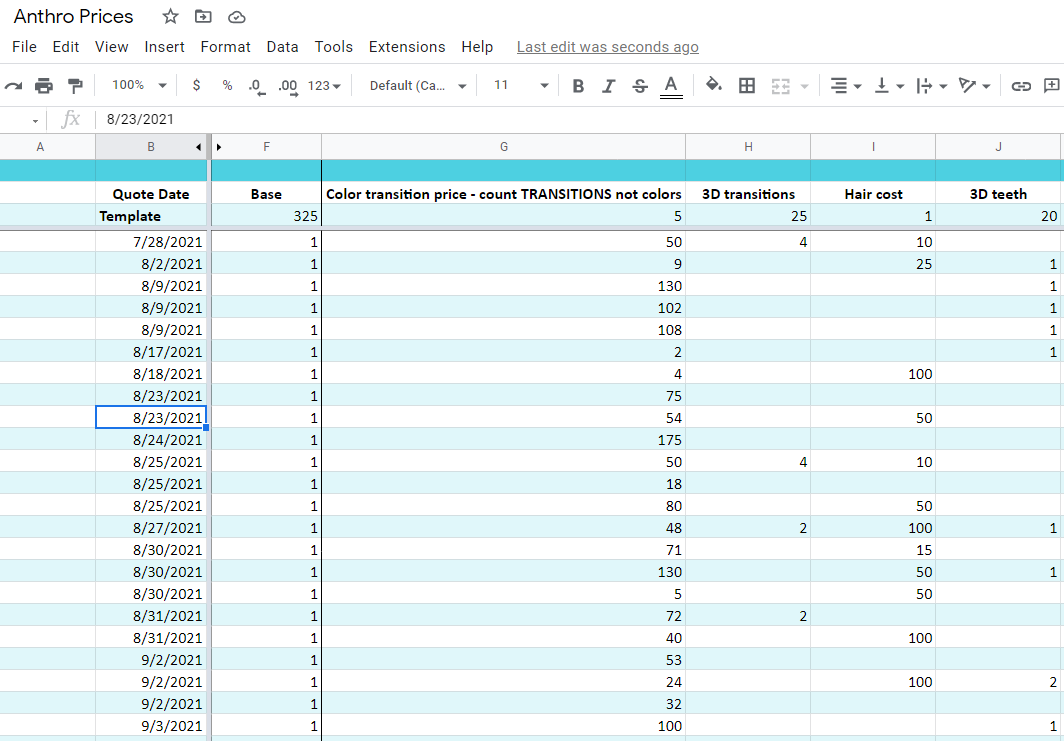

I like to use a pricing formula to price my plushies. I have a Google Sheet with all of my variables that I use to price a plush. That way when I get asked for a quote or when I price a commission I can enter in the factors that affect my price and quickly get a result! It removes some of the guesswork from pricing. Because I work off of a lot of base patterns, I start with a base price per pattern. This is the cost for making a plush with this pattern in a single color with no complicated embroidery. I determined it using a similar method to the hourly method above. From there I have determined costs for commonly seen features: color transitions, 3D teeth, claws, clothes, etc. I determined a standard price for these additions and then I can add in the features depending on the character. So I can quickly do an exercise like: how many color transitions does this character have? (to me, color transition = where I need to do applique or a color blocking seam, so depending on the design 1 stripe can actually count as 2 transitions); do they want mochi or minky paw pads? do they want 3D teeth, claws, etc? I can just quickly type into my spreadsheet these figures and it multiplies it out for me. For more subjective features like hair, wings, etc. I will estimate a price for the design instead of relying on pre-set prices. After the subtotal is multiplied out I adjust the total cost for Paypal fees and currency fees. I have an after-the-fact multiplier that increases my total price by a set factor and this is what I use to adjust my prices annually. That way I don't have to recalculate all my base prices. So for example if I ran Drago through my spreadsheet I would come up with a price of $610. That's only $5 lower than my calculated price of $615 using the hourly method, which is pretty darn close!! If you're spreadsheet-savvy you can set one up like I have in Excel or Google Sheets (I like Google Sheets because I can easily access it from multiple computers). It operates off the base price of items in the 2nd row and uses sumproducts to calculate out a subtotal. I also have the date, email address, character name, etc. that can't be seen in the snapshot below but is important for you to keep track of, especially if your quotes "expire" after a certain amount of time. I also mark in the first column whether they ended up applying for a commission so I can easily filter (this is done manually upon reviewing commission applications). It may take some additional time to translate the hourly method into a spreadsheet, but I think it saves time in the end if you are using the same base patterns and just customizing the character every time. If you are drafting a pattern completely from scratch it's probably a better idea to do the hourly method. On Giving QuotesI gave out quotes for years because it can be difficult to gain customers if they don't know exactly what they are paying up front. But at a certain point you will give out more quotes than customers you can take on, so at this point you need to evaluate your stance on quotes. It's also important to realize that the amount of truly interested customers can be a small fraction of the number of quotes you give out. So how do you cut down on the amount of quotes you give out? One method is to make a detailed pricing guide like I have, which you can direct your customers to, and say that you do not give out detailed quotes in advance. Then if you accept their commission, you can give them the price, and at that point they can accept or reject the commission. Another method is to charge for your quotes. It can be something as small as $1, or you can have people buy you a ko-fi. Even a very small dollar amount will weed out those who are truly not interested in a commission but just curious. I have also heard of people giving out quotes to Patrons only. Regardless of what you do, make sure you put an expiration date on your quotes, so you are not locked into them over a long period of time. If you give out a quote and 3 years later that person finally commissions you for that project, do you want to be locked into a 3 year old price? Probably not. I used to give a 6 month expiration date on my quotes. Because I had a spreadsheet set up, I gave out quotes for a very long time, but as I branched out into unique patterns that were harder to give out a quote for and my quote volume continued to go up I stopped giving quotes. After putting out my price guide I have only had 1 person reject the commission upon receiving the final price. So far, so good! I know this guide won't make everyone happy because I'm not telling you exactly how to price, but I hope it sheds some light on some things to consider! Happy pricing!

2 Comments

rr

7/24/2023 06:36:49 pm

oh my god, tysm !!

Reply

RadicalBoy

11/28/2023 07:07:17 pm

Amazingly detailed and helpful!! definitely going to use this as a loose guide for my new plush company!! <33

Reply

Leave a Reply. |

Archives

December 2022

Categories

All

|

RSS Feed

RSS Feed